It’s an eternal question, isn’t it? How do you raise productivity?

Whilst it would be naïve to try and cover the whole topic in one article, let me give you some ideas. We built PDCA Complete on the back of a series of productivity improvement tips. I’ll relate what we’ve done with the software with a series of seven tips.

1. Clear out the waste

Our productivity improvement tips wouldn’t make sense without our Lean origins. In simple terms, Lean is about maximizing the value you create. At the same time it is about minimizing the waste that comes along with it. Waste reduction looks at categories such as:

- Defects

- Overproduction

- Transportation

- Waiting

- Inventory

- Motions

- Processes

- Untapped human potential

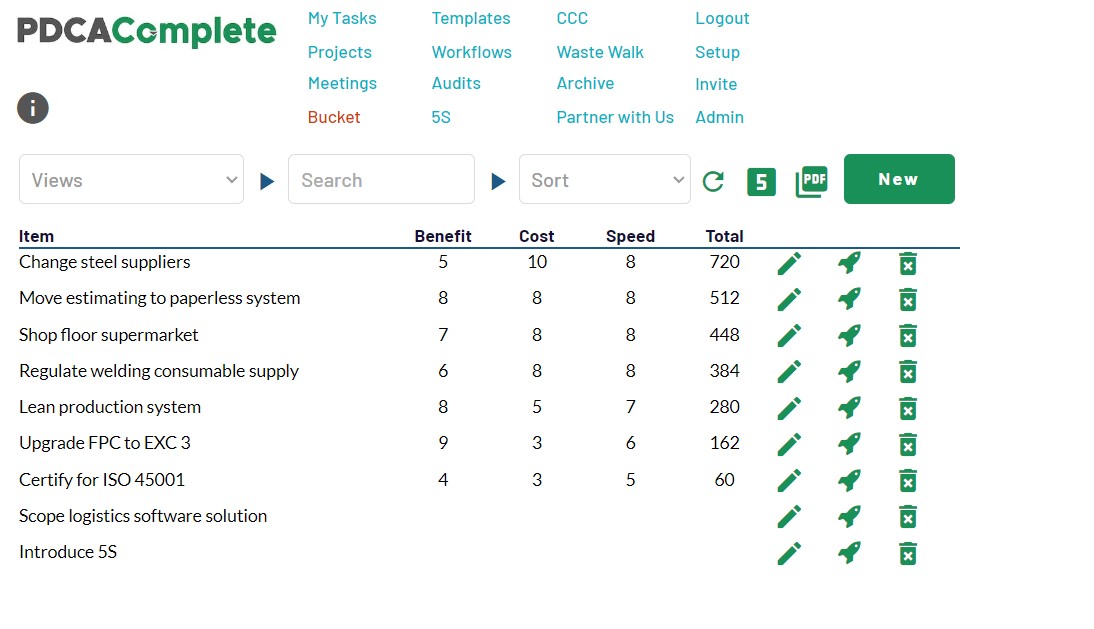

Identifying wastes (costs) and eliminating them from your business is how you increase value (profit). In PDCA Complete we have created a waste walk audit tool. You can capture the wastes you identify as you walk through your business. Each observation can then have tasks assigned against it. This speeds up the process of identifying improvements and creating a plan.

2. Reduce your time spent on admin

When we set out to build PDCA Complete, we wanted to reduce the time spent on admin tasks. The two key ones we identified first were:

- compiling meeting minutes

- managing task follow up

The Meetings module in PDCA Complete handles this. The system allows you to capture decisions / concerns and the associated actions. It is fast to input so you can capture these actions during the meeting. No more need to create separate meeting minutes. With the My Tasks function there is less of a need to chase people up about their tasks. Our feedback has shown that using My Tasks the team work their way through the list of tasks with less prompting. As long as the tasks are visible they have a chance of being undertaken.

To help improve this area further, Meetings has a standard agenda function. Also, you can chain meetings together. This allows you to review previous outstanding actions fast. I’m sure you can see why this point is in our series of productivity improvement tips!

If you want to see how much your meetings and actions management is costing you, check out our calculator.

3. Work on your best improvement first

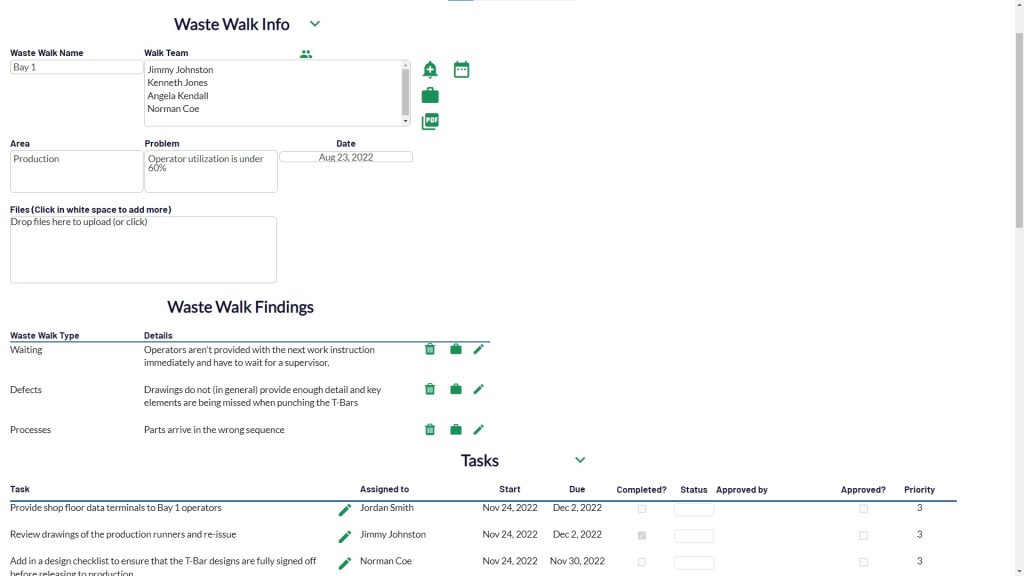

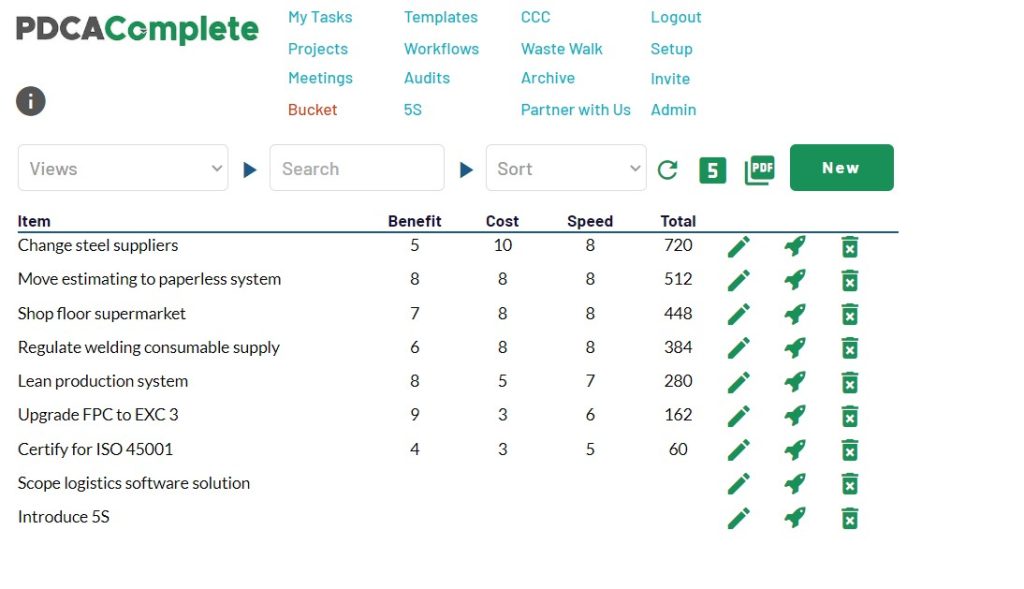

Not all improvements are equal. In PDCA Complete we have a prioritization system called BCS. BCS stands for:

- Benefit

- Cost

- Speed

Or, put another way, an ideal improvement is one that:

- can bring dramatic improvement to your business

- is free

- you can complete it this afternoon(!)

It seems logical why this is in our list of productivity improvement tips. You can’t work on your improvement opportunities without considering the effort and impact.

The BCS system lives in the Bucket module. This allows you to queue up potential improvements, to get them out of your head. When you are ready for your next improvement, rank them using BCS. The Bucket screen lists them in descending order. The next one to work on will be the one at the top of the list.

4. Capture concerns on the fly

As you walk around your business, or discuss it, issues will emerge. Many of these issues get brushed off. We’re all too busy at times but capturing these items for later is a great strategy. In fact, when it comes to productivity improvement tips, this is often my first port of call.

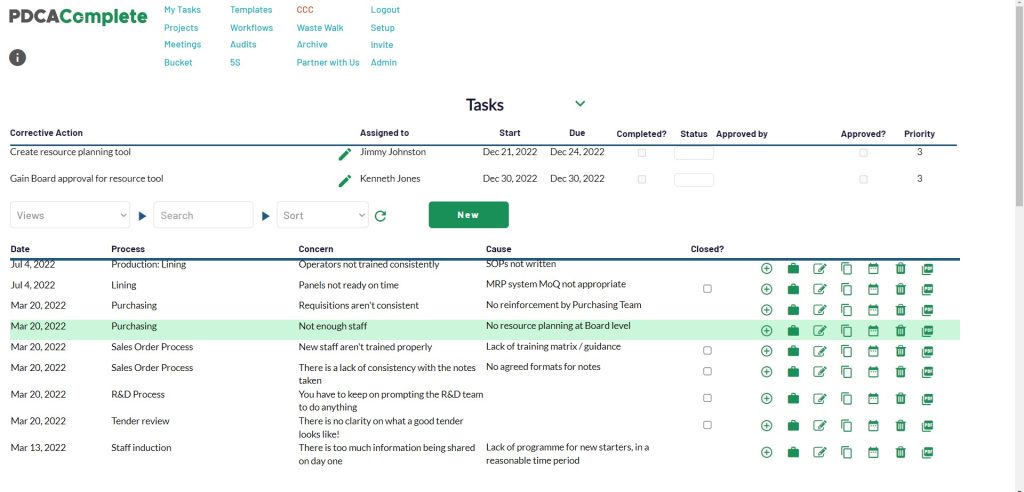

The technique that underlies this we call either CCC or 3Cs. The Cs stand for:

- Concern

- Cause

- Countermeasure

It is a simple technique and one that, unfortunately, people overlook. Don’t let the simplicity fool you. This is a powerful tool for your toolkit. Capturing concerns is the key here. You and your team need to get proficient at spotting and articulating concerns. These are things that aren’t going well, could be better, things that are missing etc…

After you have spotted them, possibly at a later time, you can evaluate them and determine a root cause. This cause should lead to an action (countermeasure). The root causes you identify should answer many concerns on your list. This makes it an effective and efficient improvement method.

We’ve included CCC in PDCA Complete. You can identify processes that you have concerns with. Capture the concerns and later add the root cause and countermeasure. The countermeasures flow into the My Tasks screen. This then allows your team to work on the actions in one place. No need to jump between twenty different action plans!

5. Value your time and focus

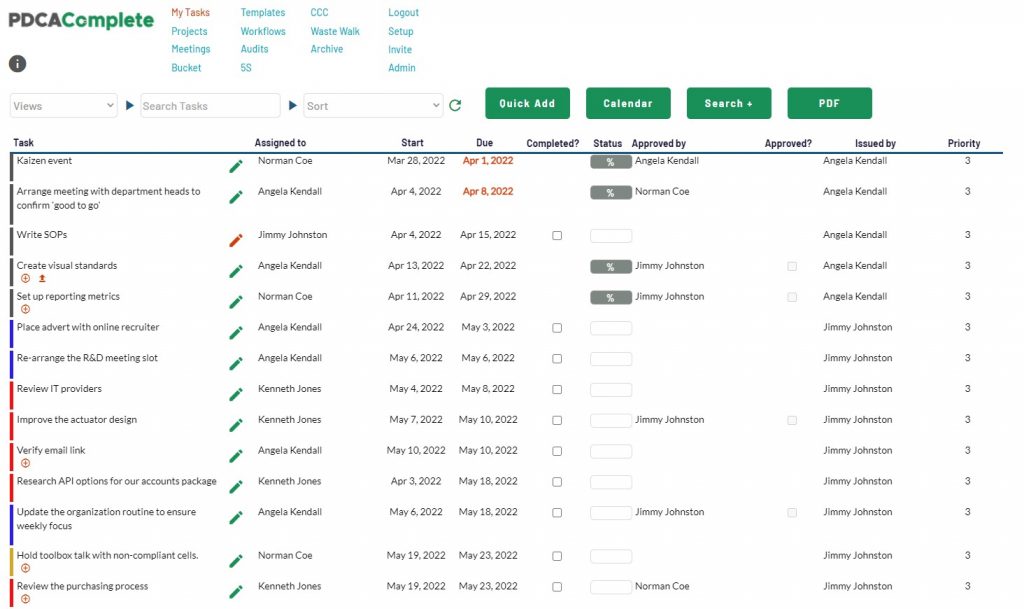

You can’t spend your time doing everything. Having the ability to focus on specific activities and stick with them until completion is a skill. When we built PDCA Complete we wanted to make sure we could do this. The result was the My Tasks screen.

My Tasks allows you to slice and dice all the tasks linked to you. You can focus on:

- The tasks assigned to you

- The tasks you have assigned to others

- Approvals that you need to sign off

- Your teams’ tasks

- Tasks where you are a stakeholder

You can change the sequence by date, priority, recent activity etc… You can also see at a glance which items your team have updated thanks to the visual flags. There is even an advanced search if you want to tighten up the focus further. Of course, you can use the filtering within specific projects too.

To become more productive you need a clear focus. The tools in PDCA Complete can help you to achieve this.

6. Focus on process delays

The gaps between steps in a process, or processes themselves, is a source for improvement. You can measure too many process lead times in days when the work content is hours. When you identify the gaps, the dead time, you can re-engineer your work.

Re-designing your processes is outside of the scope of this article. Spotting the delays and adding them to your concern list is the point here. If you can spot them, and re-organize yourselves, significant change can happen.

We address this in PDCA Complete with our Workflows module. This allows you to digitize your processes into a series of time bound actions. Each task has a start time and duration. The start time is from the start of the workflow, which you can launch on a single or recurring basis.

You can select whether steps need approval and increase the visibility of who needs to do what, when. This visibility can help to remove the gaps in your processes.

7. Look for ideas outside of your business

Finally, let’s not put all the pressure on you here! There are good ideas in other businesses that you can borrow from. A good quote I heard years ago was:

“If you have a problem with queues, see what people who manage queues do. Check out an airport or Disney.”

The point is that other businesses in other sectors may have similiar challenges to you. Have a look at how they handle the issue and distil the principle. Bend the principle so that it fits your business and then define your project to install it.

If you don’t have time right now for the project, add the opportunity to the Bucket. You can do it later when you have more time. Don’t lose the opportunity!

Increased productivity

I hope that you have found some useful points in this article for productivity improvement. This is our shortlist and I also hope that you can see how PDCA Complete can help. We want businesses to have an easier time and be more productive.

If you haven’t claimed your free PDCA Complete subscription then do it today. The free subscription allows three users to access all the primary features. The users don’t have to be in the same business, by the way. The paid subscriptions allow you to have more users and more features. Extra features include PDF reporting and file uploads. You can sign up for your free account here.

Good luck with your improvement journey.